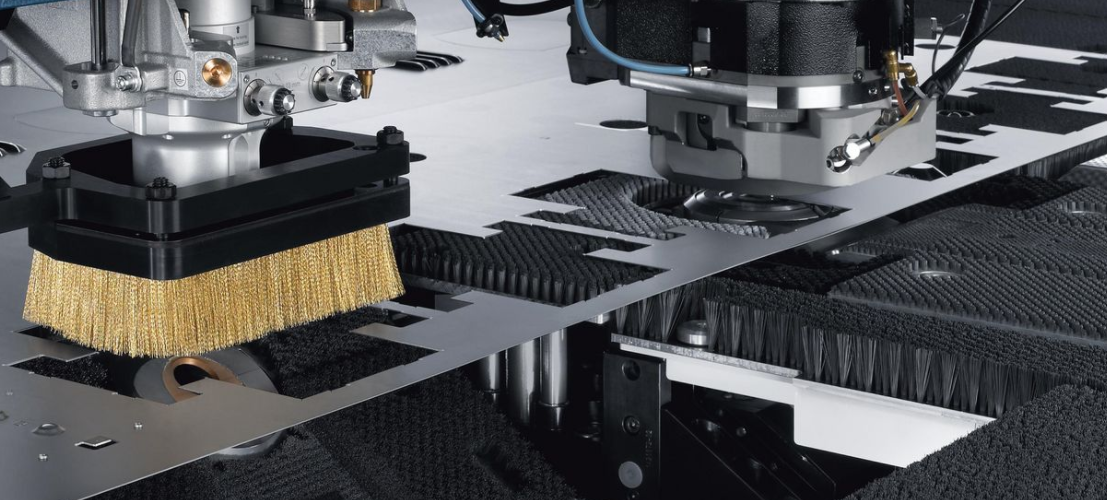

With the advent of laser technology, laser punching and cutting machines are a masterpiece of advanced laser machines and tools. Unlike traditional punching machines that can create hole-intensive parts, the machines using laser can create the same results faster and quicker.

The combination machine provides versatility and allows fabricators to benefit from each process. When the cutting speed of this combo machine combines with the punching feature makes this machine versatile and cuts the requirement of some secondary jobs.

Most people think that a combo machine can also do welding. But it is wrong to say that a punching/cutting machine can do welding. A punching machine using a laser has a head that cannot be used for laser welding operations, the same as the head of the welding machine is not able to do the cutting.

The punching machine using laser technology is very efficient and has become a powerful tool that can generate intricate features, and it can produce standard holes with a single stroke. So if you are willing to save time and money as well, you should go for the combination machine in which cutting and punching features are involved.

Moreover, a combo machine offers maximum process throughput. In general, the fabricators are able to create low-volume but a variety of different parts mix. This fabricator ensures the speedy and most efficient throughput. So a combo machine offers several benefits to the customers because a properly programmed machine is able to achieve the greatest throughput in the manufacturing environment.

Another reason for choosing a combo machine is that it permits fabricators to be more productive even without using an extensive tooling library. This offers maximum flexibility as it is essential for any fabricator that has to meet short lead times. Plus, the combo machine can fit all the approaches, including:

- Labour costs

- Non-value added time

Even after limiting the handling and secondary operations, these combo machines are able to offer greater impact than the sum of their parts. It can even uncover inefficiencies across the board, even all those areas that are tough to quantify.

Furthermore, these machines provide 25% more speed as compared to other cutting and punching machines. The modern machines have increased in processing speed. It is not because of the punching, but the increase in processing speed is also because of unattended part sorting. So the laser punching and cutting combo machines are the best to choose.